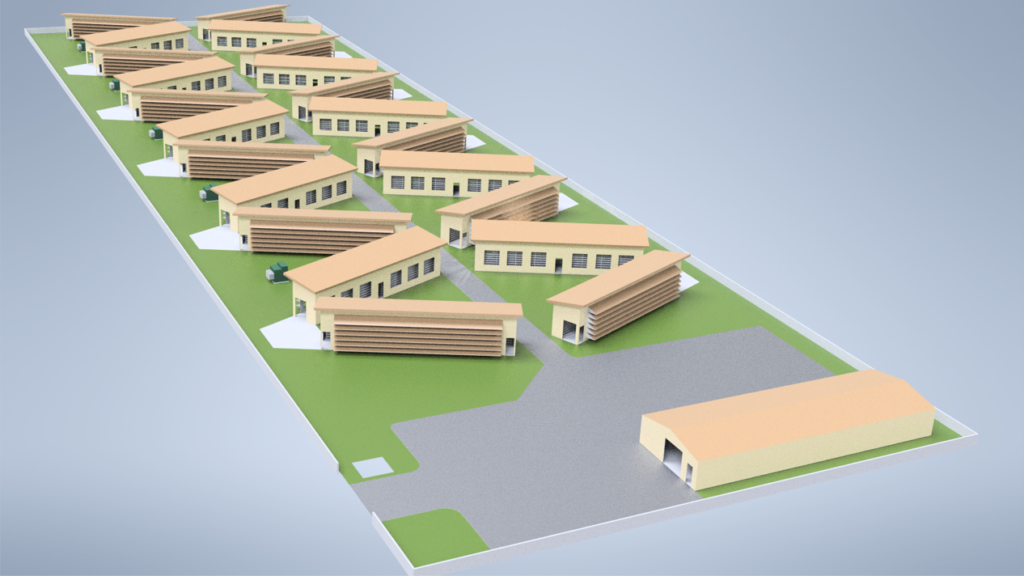

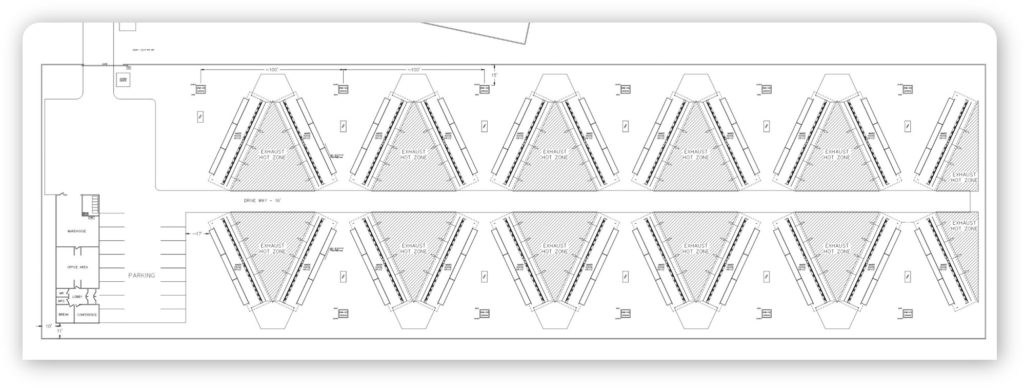

A greenfield, 25-megawatt data center in Kentucky. The site went live in Q4-2021.

What's in a name?

Sophie Wilson is a detailed oriented designer who helped invent and deploy ARM technology. This was key to unlocking the mobile and custom chip revolution. She found ways to use processors in more simple ways. We’re building a data center to help the grid. We’re using the ways of Sophie to blend details and simplicity for our first greenfield project.

Learn about SophieProject Timeline

2021